AGILITY OPTIONS-WMS

Agility WMS is a robust system with many possible configurations. These configurations can mold the system to operate according to individual business process needs. This section is designed to walk through all the configurations in WMS Setup.

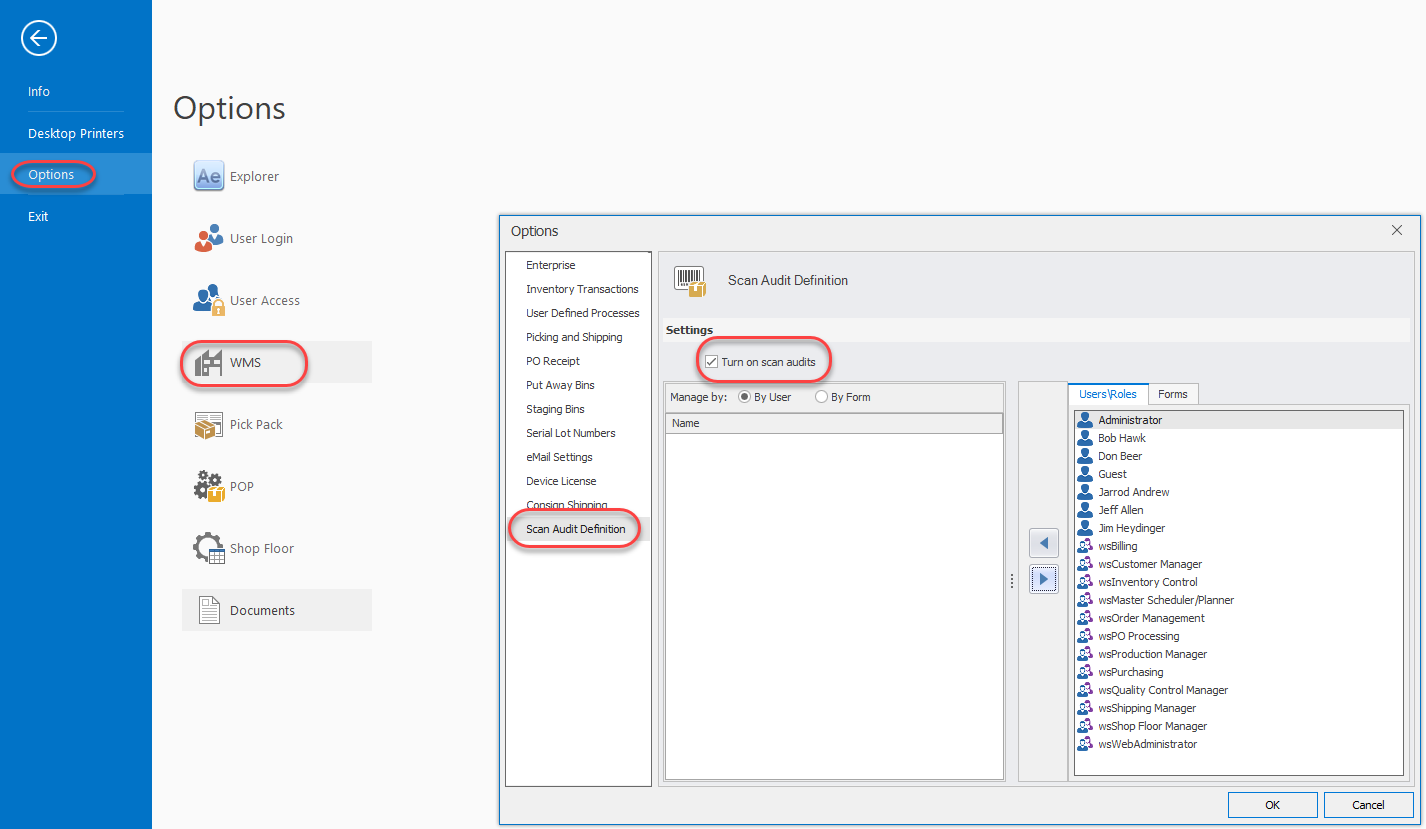

To begin, navigate in Agility to File > Options > WMS

Figure 1: WMS Options

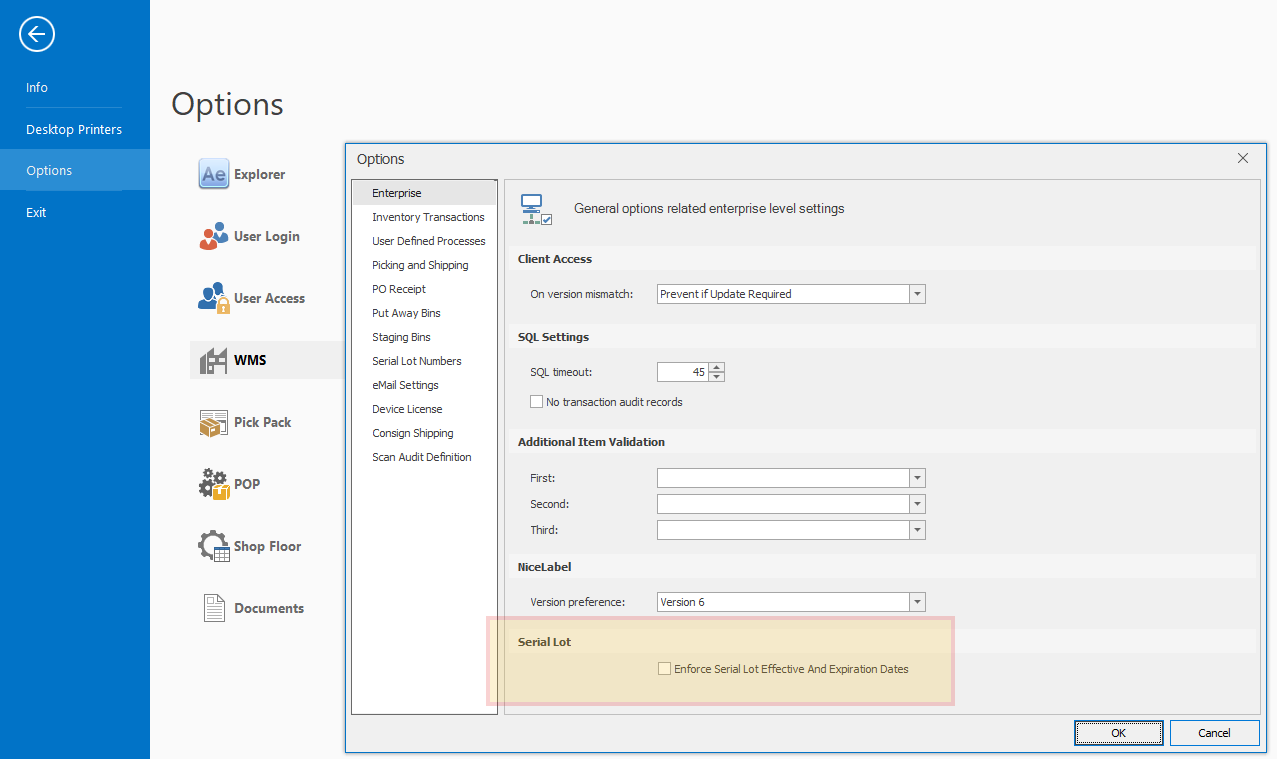

ENTERPRISE

The Enterprise screen sets general options related to enterprise level setting.

Figure 2: Enterprise Options

Client Access Select from “Warn to contact administrator” and “Prevent if update Required” when a version mismatch between the server version of the software and the client version of the software is discovered.

Warn to contact administrator: Choose this setting to present a warning dialog to your users when they launch Agility and the workstation needs to be updated.

Prevent if update required: Choose this setting to stop your users from loading Agility at all and therefore stopping any chance for them to commit transactions with outdated software that might corrupt your business data. .

SQL Settings SQL timeout: This field sets the number of seconds to wait while attempting to execute a SQL command before canceling the attempt and generating an error. Select between 30 and 300 seconds.

No transaction audit records: The WiSys transaction objects write various records into a SQL table called WiErrLog. These records can be used to debug some transactions. This table can contain a large number of records. Check this box to prevent these transaction audit records from being written.

Additional Item Validation: This section allows you to define up to three fields on the item master, which will be included in any item scan in Pocket ES. For example, if user_def_fld_1 is chosen, then you can scan any data that is in user_def_fld_1 and it will translate to the item number.

NiceLabel: This section allows to select the version of NiceLabel that you will be using. Note that Version 6 is only compatible with WiSys Build 563 and later.

Enforce Serial/Lot Effective And Expiration Dates When this option is turned on, existing Lots that are received into a new location or bin will retain their original Effective and Expiration dates.

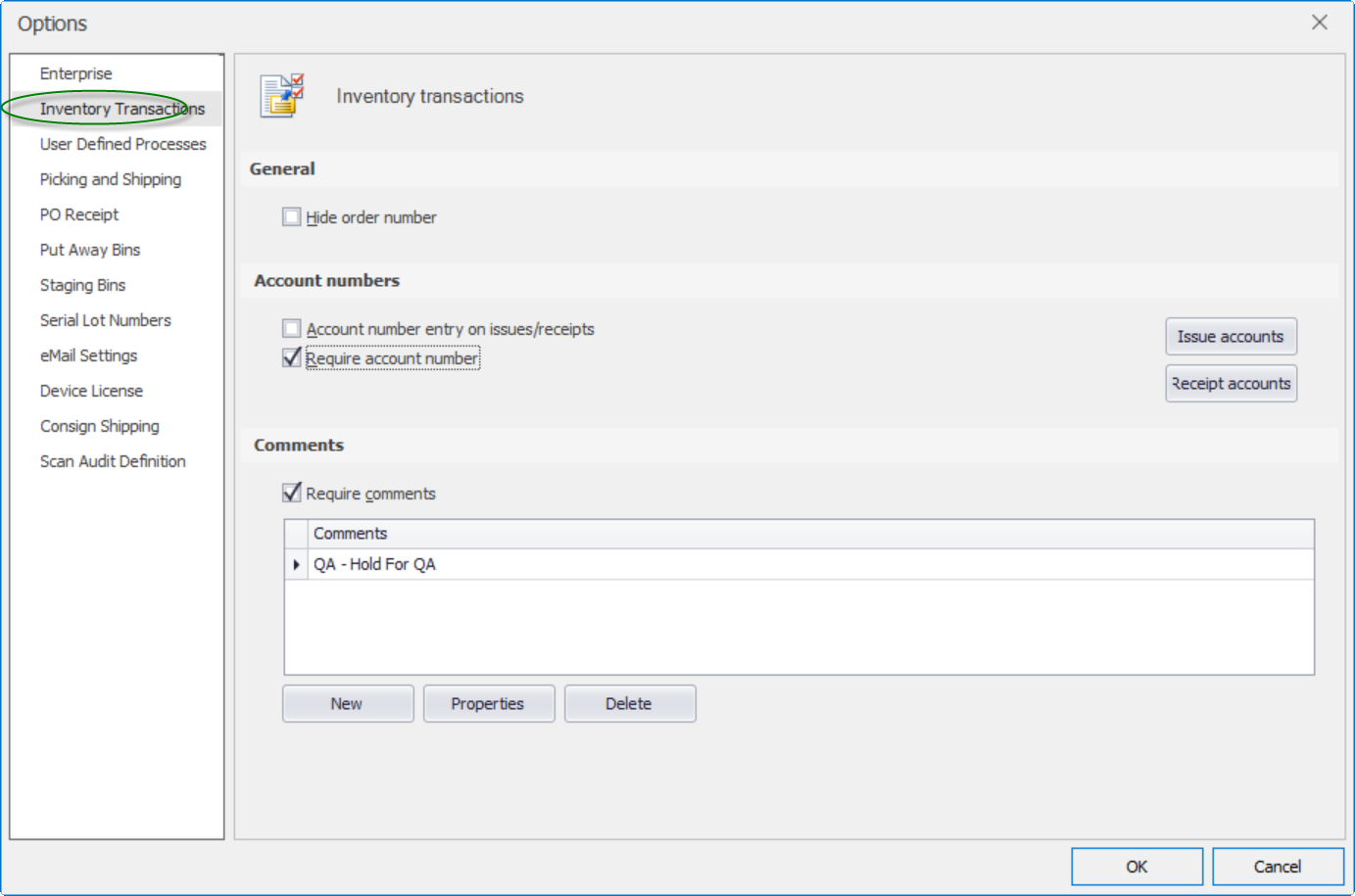

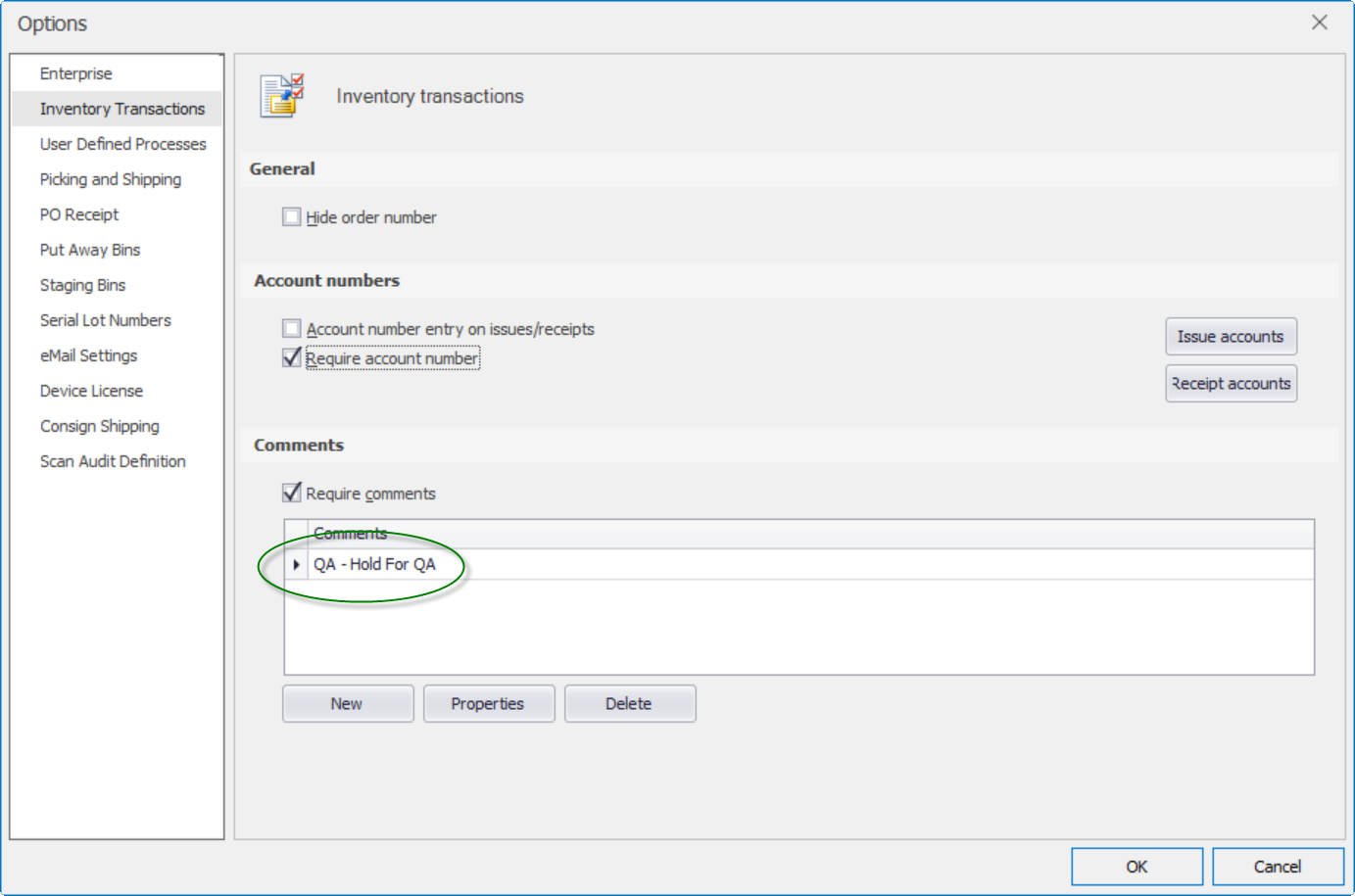

INVENTORY TRANSACTIONS

Figure 3: Inventory Transactions

General

Hide Order Number: By default an order number is presented to the user in the inv trx module on the handheld device. This field populates the do order number on the iminvtrx_sql table. Checking this box hides the order number on the screen.

Account Numbers

Account number entry on issues/receipts: When checked, this box allows the user to specify an account number to issue or receive against. Use the Issue Accounts and Receipt Accounts buttons to select GL accounts and cost centers.

Require account number: Checking this box requires entry of an account number.

Comments

The inventory transaction modules on the handheld devices allow the user to type or look up a comment. Comment maintenance is used to specify pre-determined comments for the user to look up.

Require comments: When checked the inventory module on the handheld device requires the user to type or lookup a comment.

To create comments, click on New.

When the Comment Maintenance screen appears, enter a Comment Code and Description and click OK.

Figure 4: Comment Properties

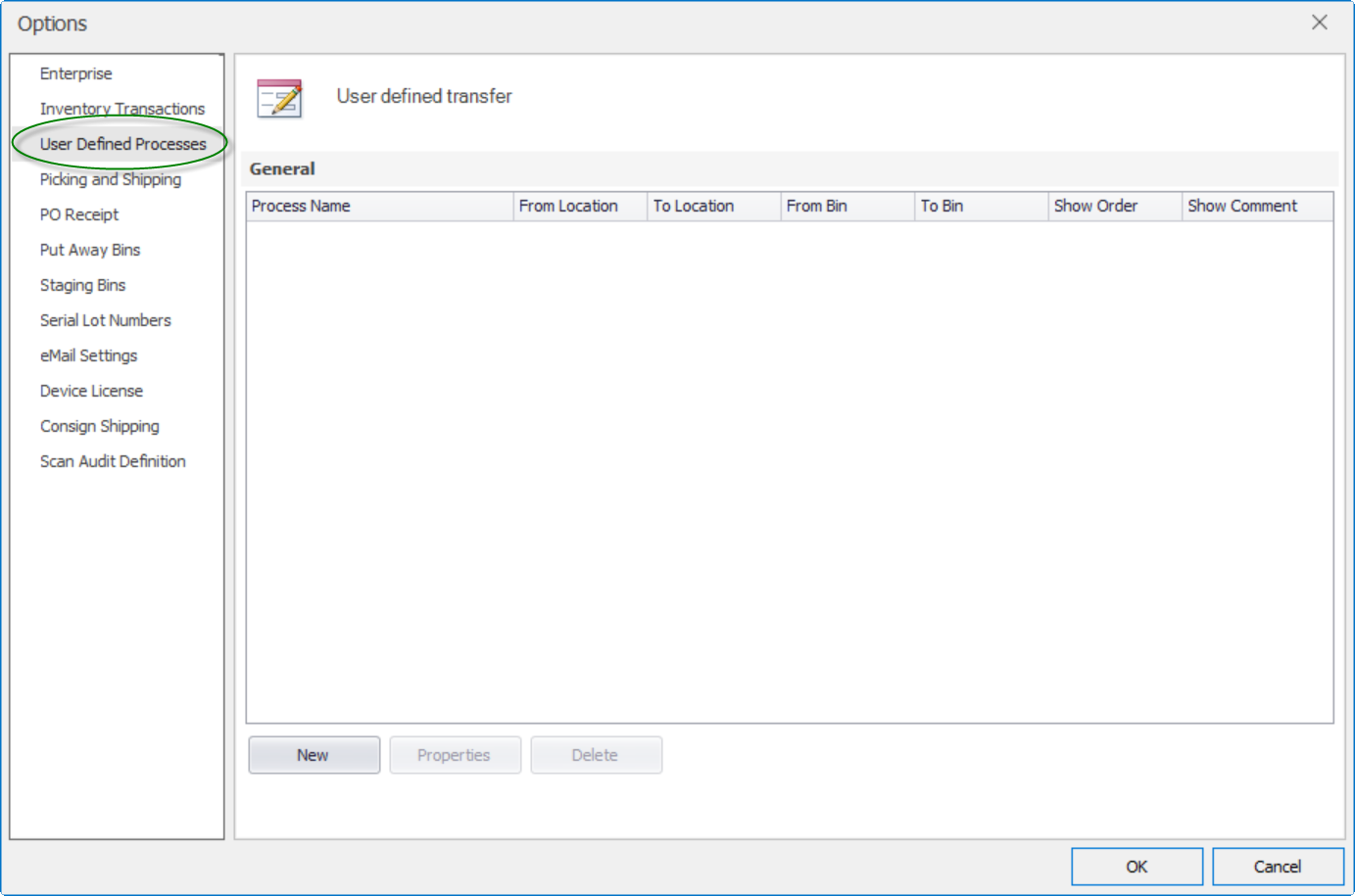

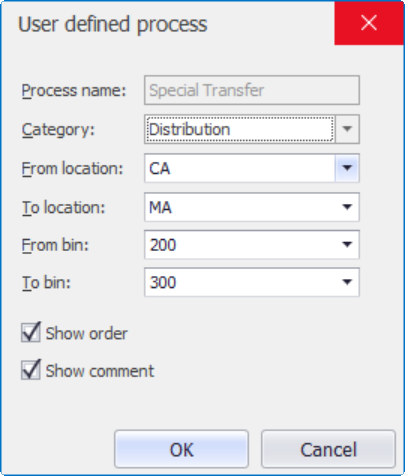

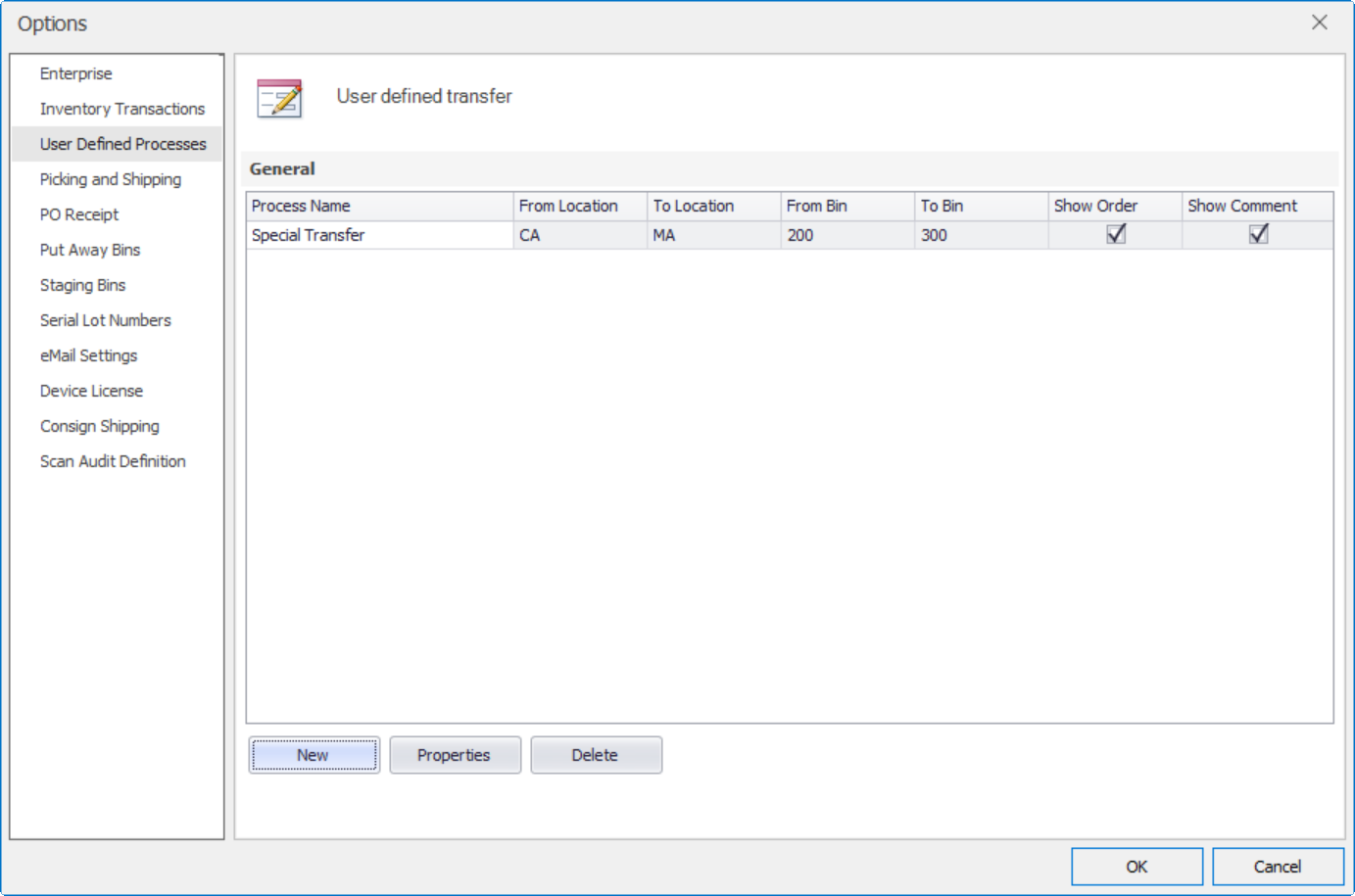

USER DEFINED PROCESSES

A new process can be created in Options. A process consists of at least two locations and one user. A bin can also be specified. Once a process is defined, a new icon will appear on the handheld, which allows the user to transfer material very quickly based on the pre-defined conditions.

Figure 5: User Defined Processes

Click on "New" to open a dialog box.

In the dialog box, enter a name for the new user defined process.

In the drop down box, select "Category".

Enter To and From Locations for your transfer.

If either of the locations in the transfer is binned, enter the bin.

Check the corresponding boxes if you wish to display order and/or order comments. Click OK to save the selections.

The new module will be available to users who are given access through User setup.

Figure 6: Creating User Process

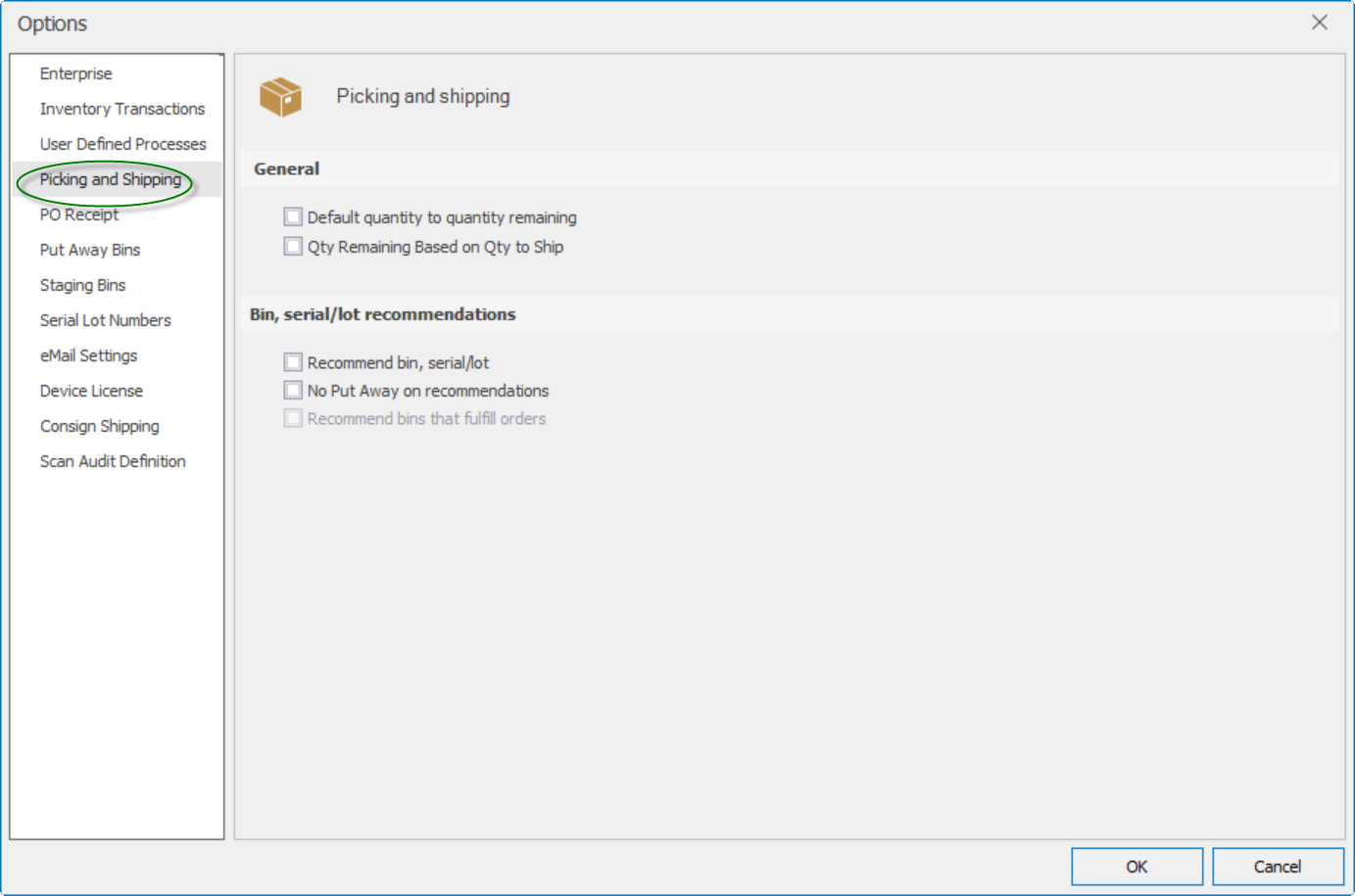

PICKING AND SHIPPING

Figure 7: Picking and Shipping

General:

Default quantity to ship quantity: When this box is checked the quantity to pick is defaulted to the quantity to ship when an item is scanned.

Quantity remaining based on quantity to ship: This option defaults the quantity on the shipping form in Agility WMS to the quantity to ship on the Macola order.

Bins, serial /lot recommendations:

Recommend bin, serial/lot: When printing pick tickets using the WiSys Pick Management grids in Agility the bin and/or serial/lot is recommended based on Macola flags. This option is designed to work with the Shipping form in Agility Mobile.

WARNING: This setting will create a hard allocation in Macola for the bin serial/lot(s) recommended. If order lines are not shipped using WiSys Shipping, the allocations may or may not clear properly creating potential issues with billing and invoicing. If shipping is done in Macola or by some other method, DO NOT check this box.

No Put Away on recommendations:

Recommend bins that fulfill orders: When recommending bins without serial/lot the pick ticket will recommend the bin that will fulfill the order instead of two different bins that add up to the order.

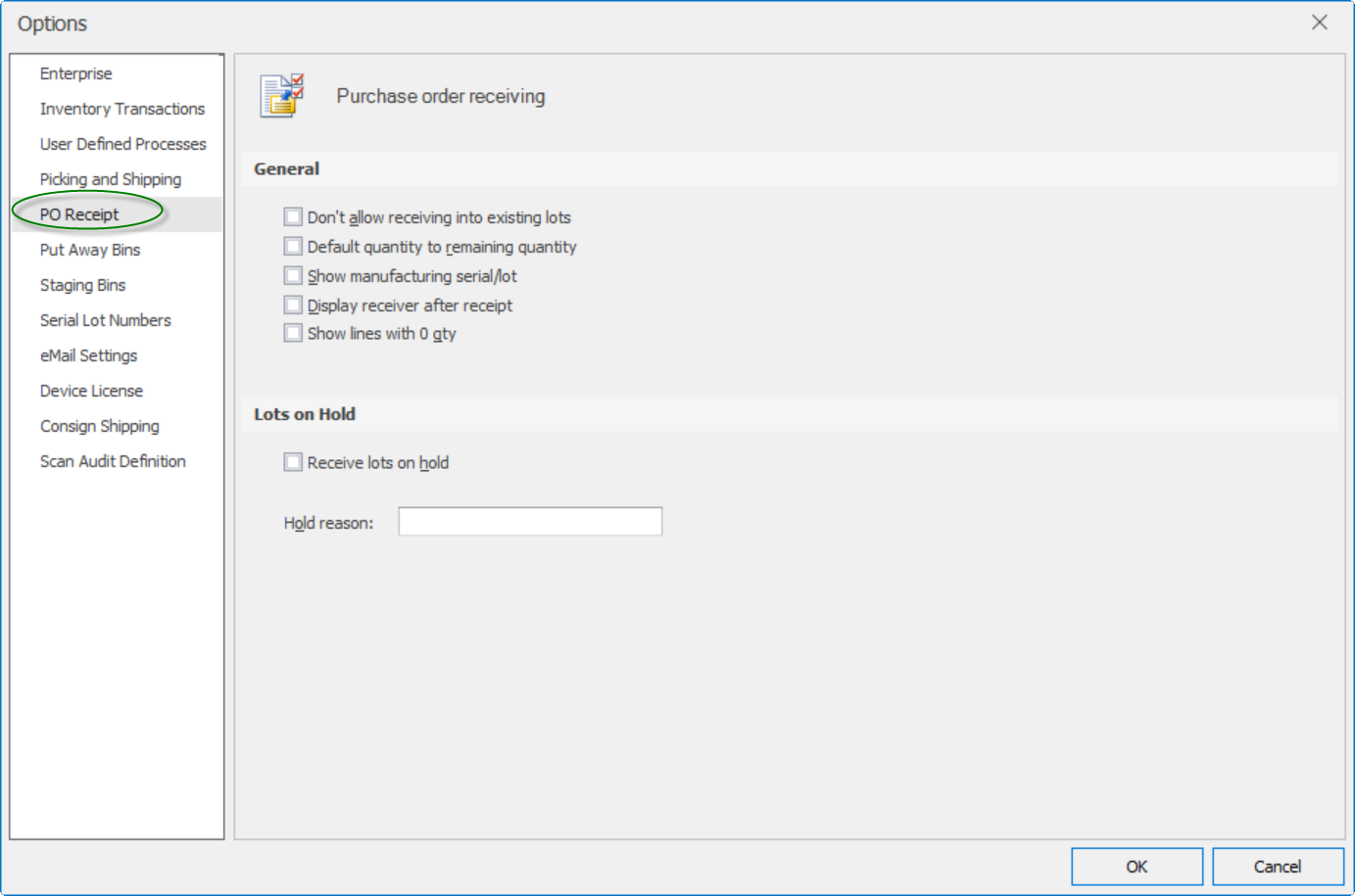

PO RECEIPT

Figure 8: Purchase Order Receiving

General

Don't allow receiving into existing lots: When selected, this box checks that the lot the user is receiving does not already exist in Macola.

Default quantity to remaining quantity: When scanning the item, the quantity is defaulted to the remaining quantity.

Show manufacturing serial/lot: By default, the MFG Serial/Lot is not available when specifying lots. This setting specifies to the system that the user should be able to scan or type in a MFG serial/lot number. Note: This option was called "Scan Mfg S/L" on previous setup option screens.

Display receiver after every receipt: Every time the user completes a receipt the receiver is displayed to the user.

Show lines with 0 qty: When this box is checked, lines which have a quantity remaining of 0 will be displayed.

Lots of Hold

Receive lots on hold: When a serial/lot is received it is place on hold immediately.

Hold Reason: If placing serial/lots on hold at receipt time, this is the reason code for putting the serial/lot on hold.

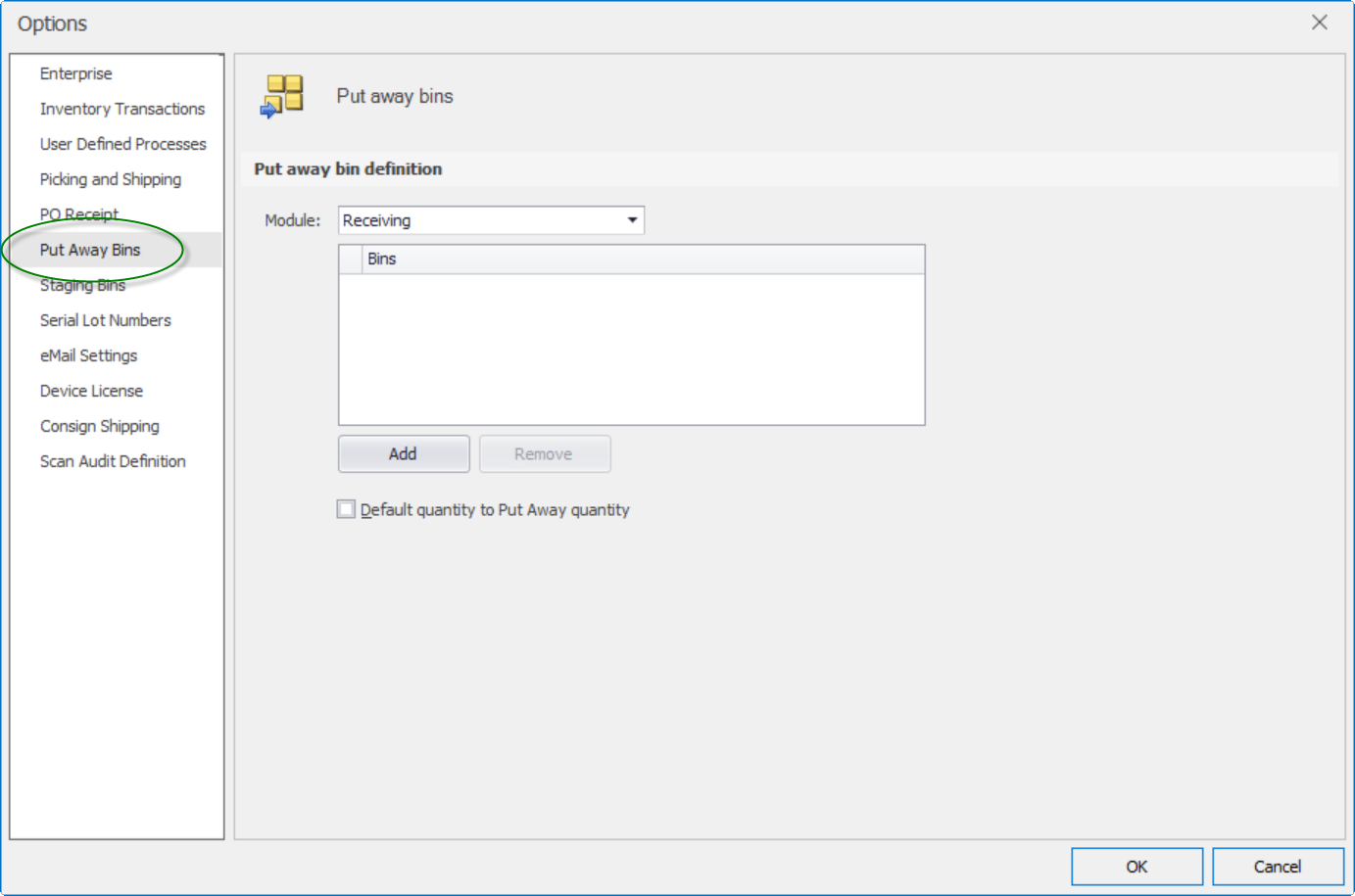

PUT AWAY BINS

Figure 9 Put Away Bins

Put away bin definition

Module: Pick a module in the drop-down, which lists the current put away bins. Type in or look up a bin to add it to the possible put away bins for that module. On the handheld device the user can pick from this list of bins to set which bin will be the put away bin for that device. This is found in device setup on each individual handheld device.

Default quantity to Put Away quantity: When scanning an item in the put away bin the quantity is defaulted to the quantity that is in the put away bin.

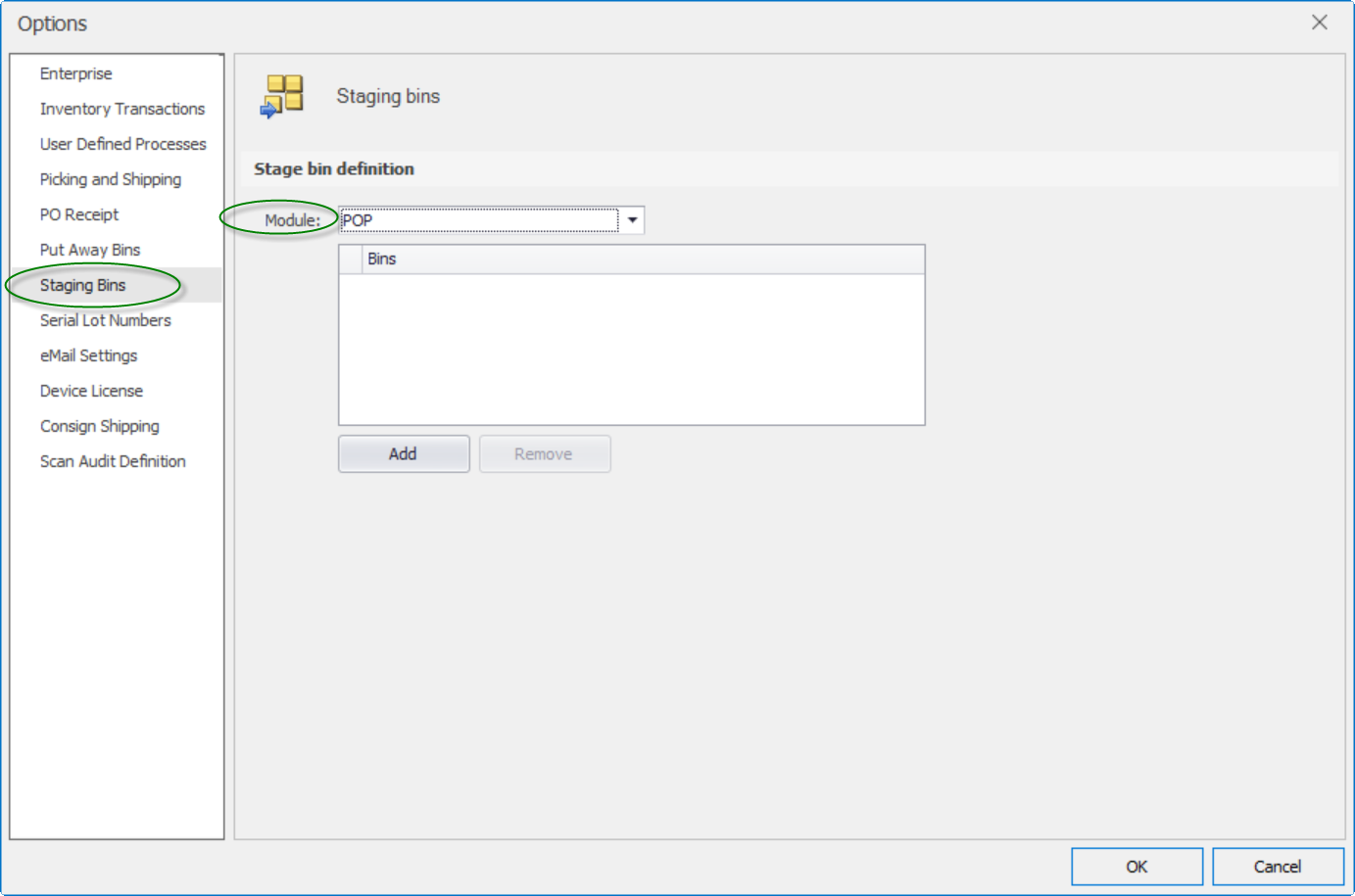

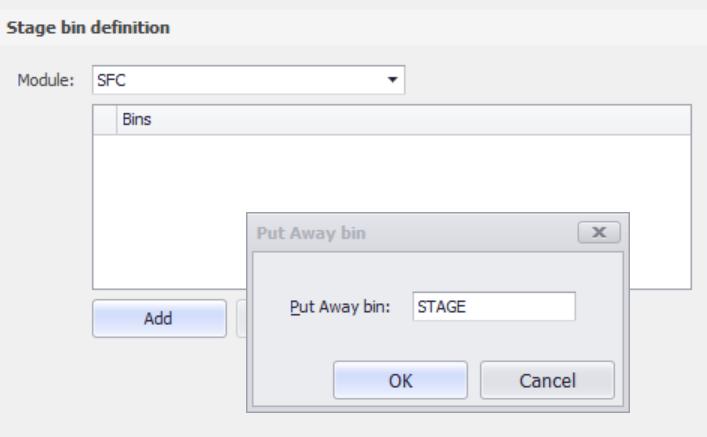

STAGING BINS

Figure 10: Staging Bins

Stage bin definition

Module: Choose between POP and SFC (Shop Floor Control)

To add a module, click the Add button. Enter the name of the Stage bin and then click "OK". To remove the bin from the listing, highlight the bin in the list and click the Remove button.

Figure 11: Adding Stage Bin

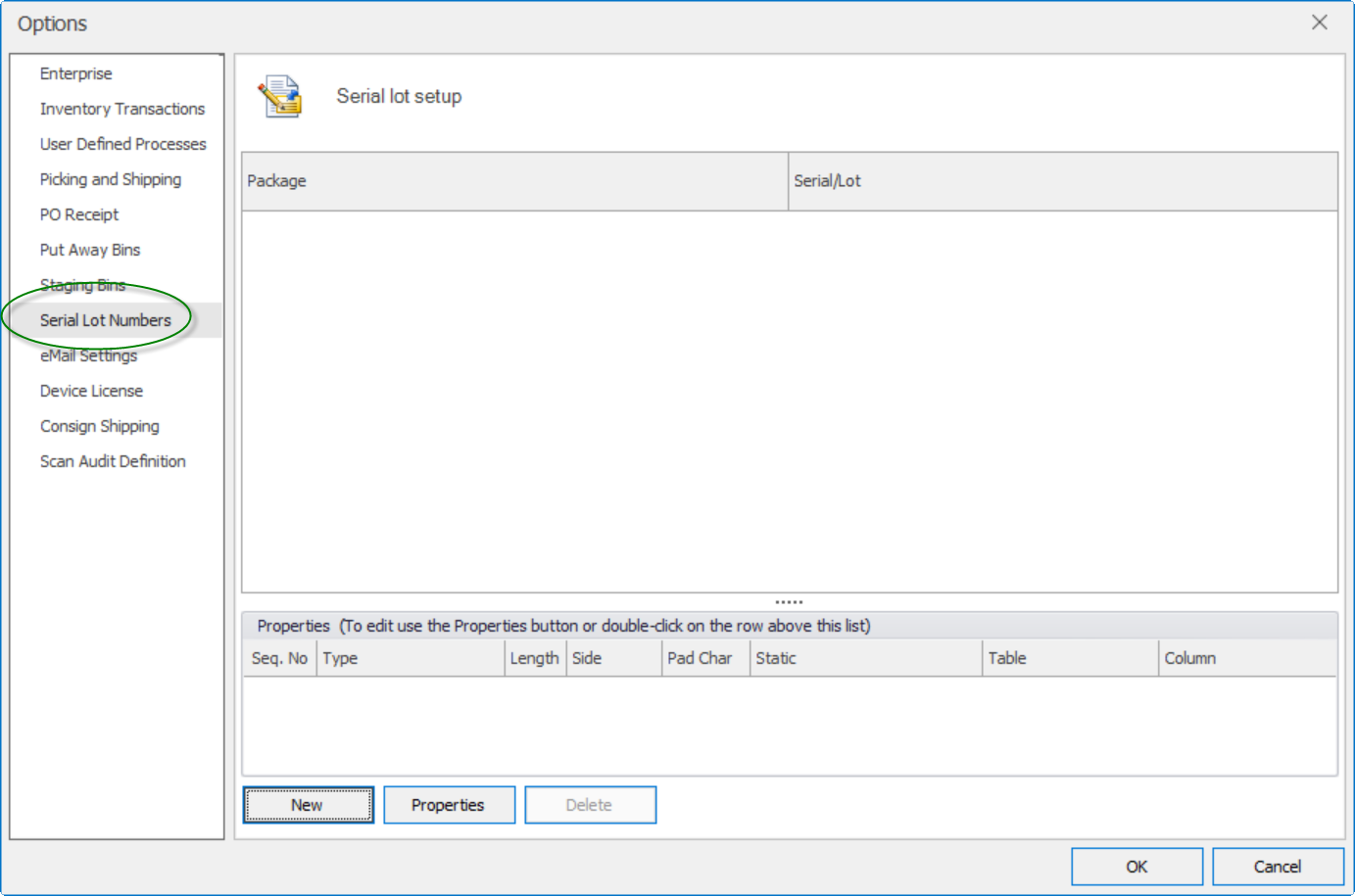

SERIAL LOT NUMBERS

Figure 12: Serial Lot Numbers

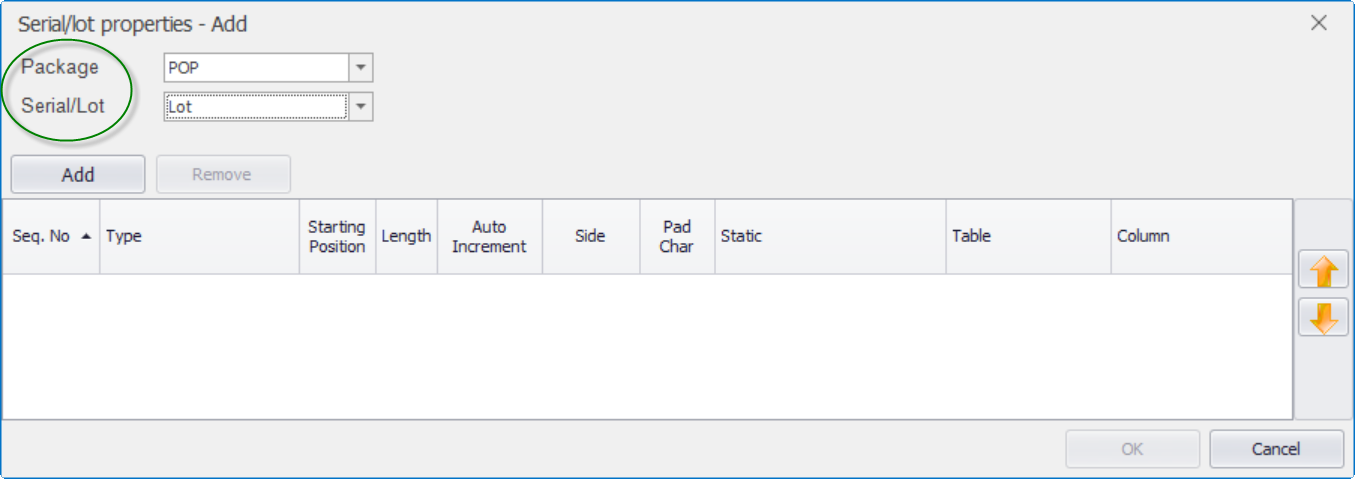

To build a Serial/Lot layout first choose a module from POP, Purchase Order, Shopfloor, Inventory Maintenance and choose whether you are building a layout for serial numbers or lot numbers (Layouts can be created for both serial numbers and lot numbers for each module).

Click "New" to start a new segment.

Figure 13: Selecting New Segment

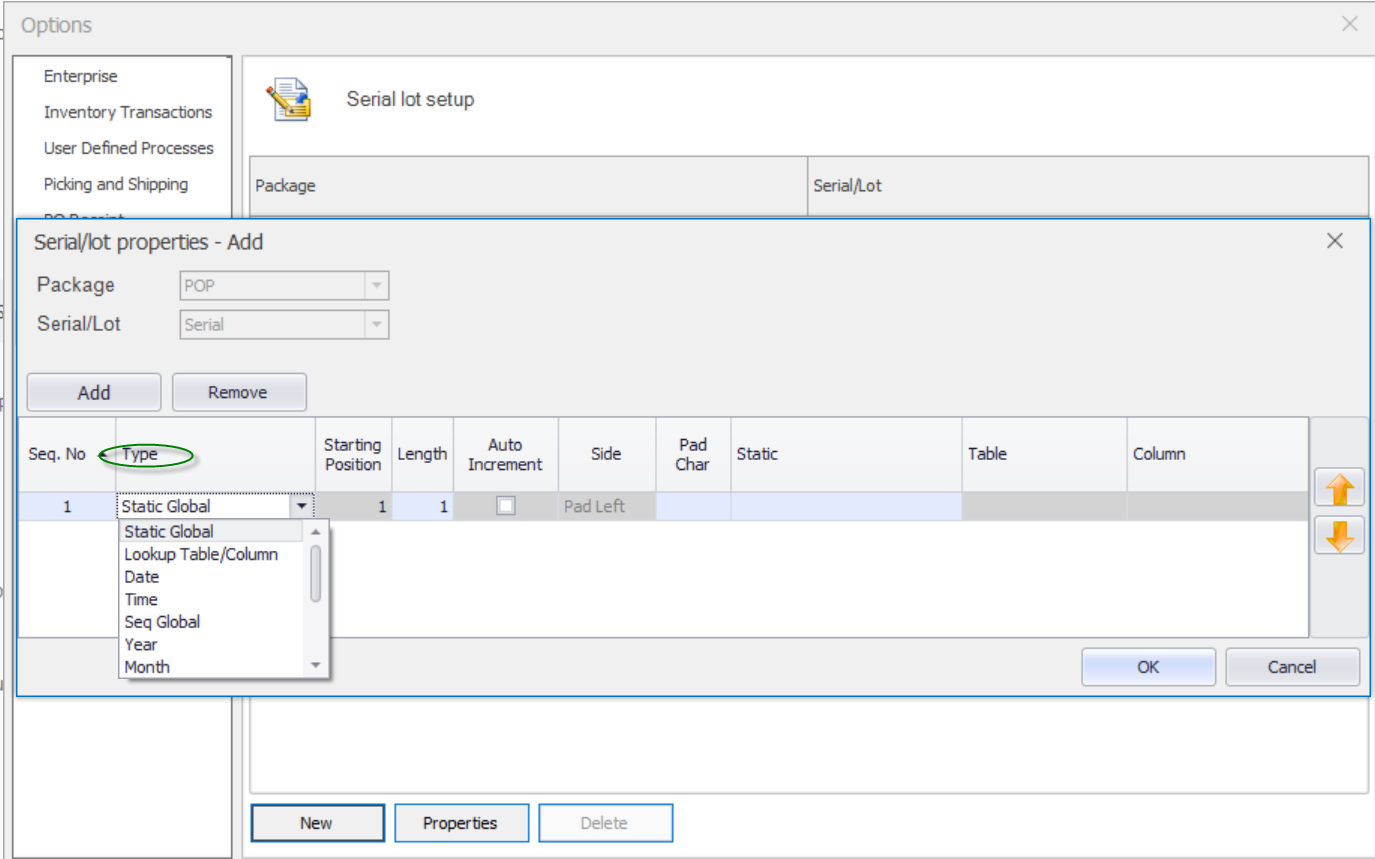

Choose a type from the drop down.

Figure 14: Selecting the type

Static Global |

Type a static string that never changes |

Look up table/column |

Pulls data from Macola |

Date |

Date stamp |

Time |

Time stamp |

Seq Global |

Continually growing sequential number |

Year |

Year stamp |

Month |

Month stamp |

Day |

Day stamp |

Julian Date |

Julian date stamp |

Day of Week |

Day of week stamp |

Day of week (Monday) |

|

Day of week (Sunday) |

|

Julian Day |

|

Macola IM setup |

Static value and Numeric value combined as defined in Macola IM setup |

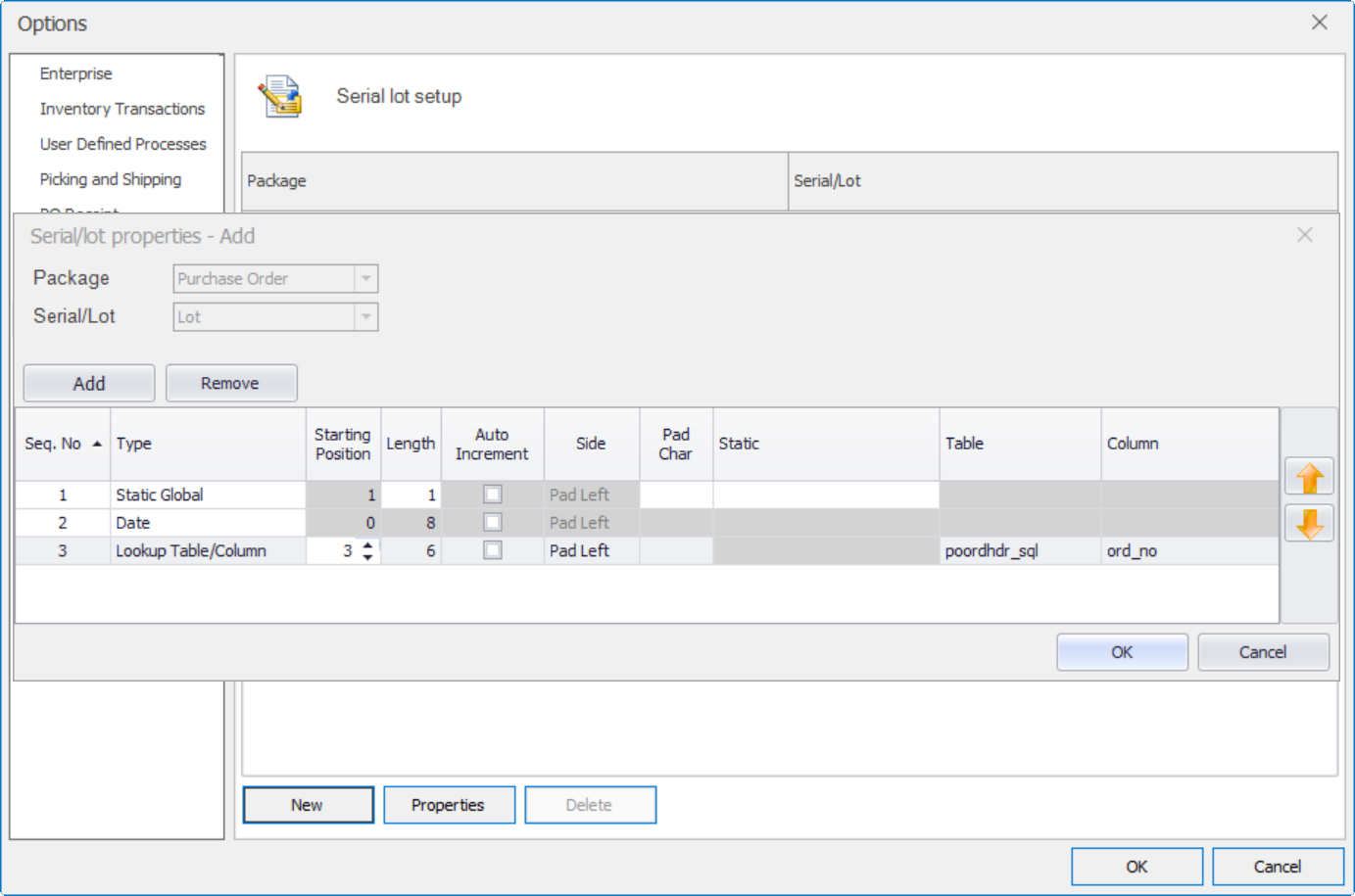

Once a type is determined, specify a length for the segment, padding side, and pad character. If the type is "Static Global" then type in a string in the "Static" field. If the type is "Lookup Table/Column", then specify a table and a column to pull data from. If the column is to be used as a sequential number then check the "auto increment" checkbox and each time the data is read it will update it by 1.

By Macola default, the total number of characters in all segments must not exceed 15 characters.

Below is a screen shot with a sample layout showing a setup screen for a PO.

Figure 15: Entering data

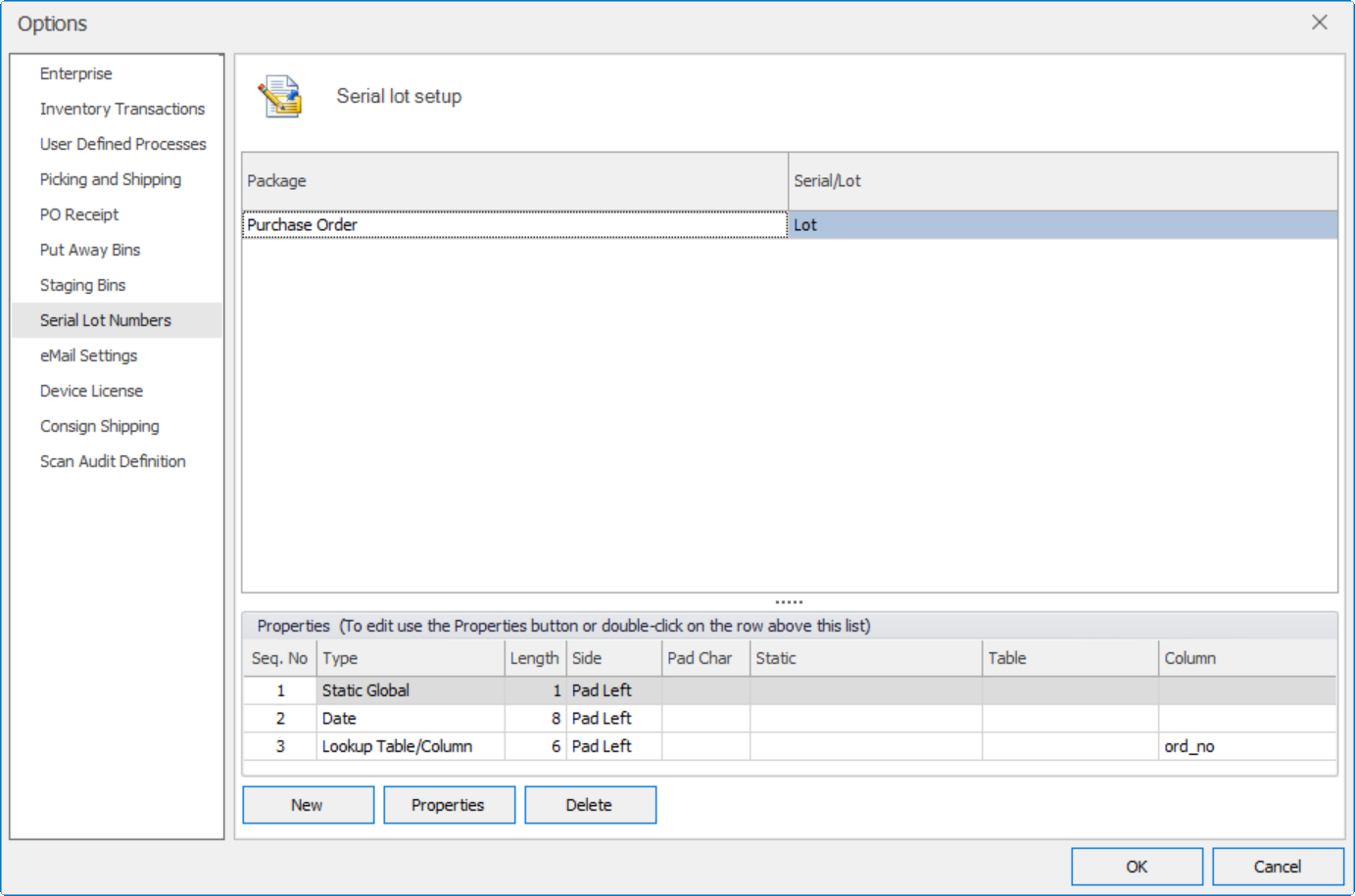

Figure 16: Completed setup

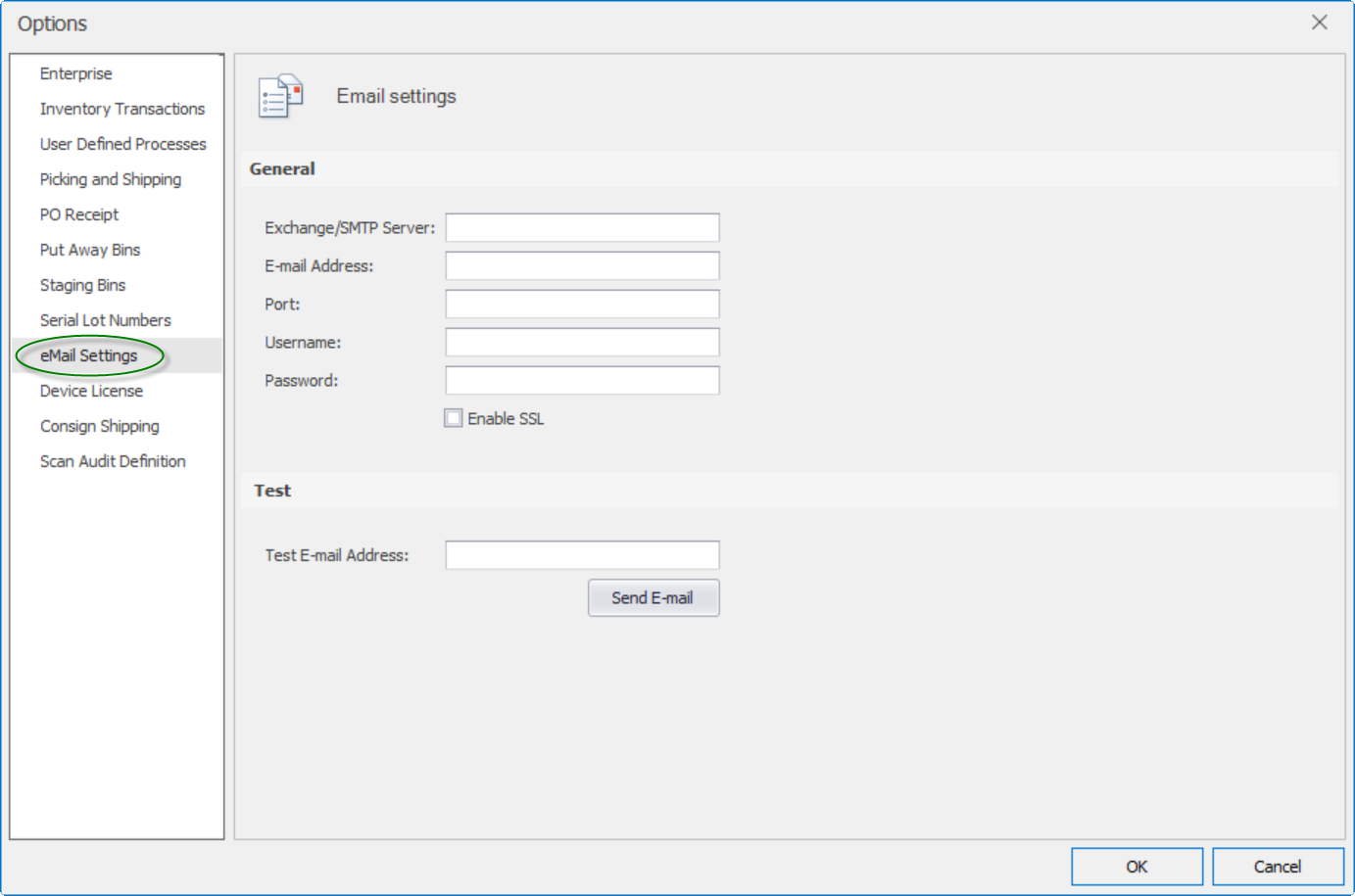

Email Settings

Figure 17: eMail Settings

General

Exchange/SMTP Server: Enter your Exchange or SMTP server in this box.

E-mail Address: Enter your e-mail address in this box

Port: setting usually set to 25 (default value) but could change depending on your email server settings

Username: Enter your email user name here

Password: Enter your password in this box

Enable SSL: Place a check on this box if your organization’s email server is set up with email exchange encrypted.

Test

Test E-mail Address: Enter your e-mail in this box and click the "Send E-mail" button. A test e-mail will be sent to your inbox if your settings are correct.

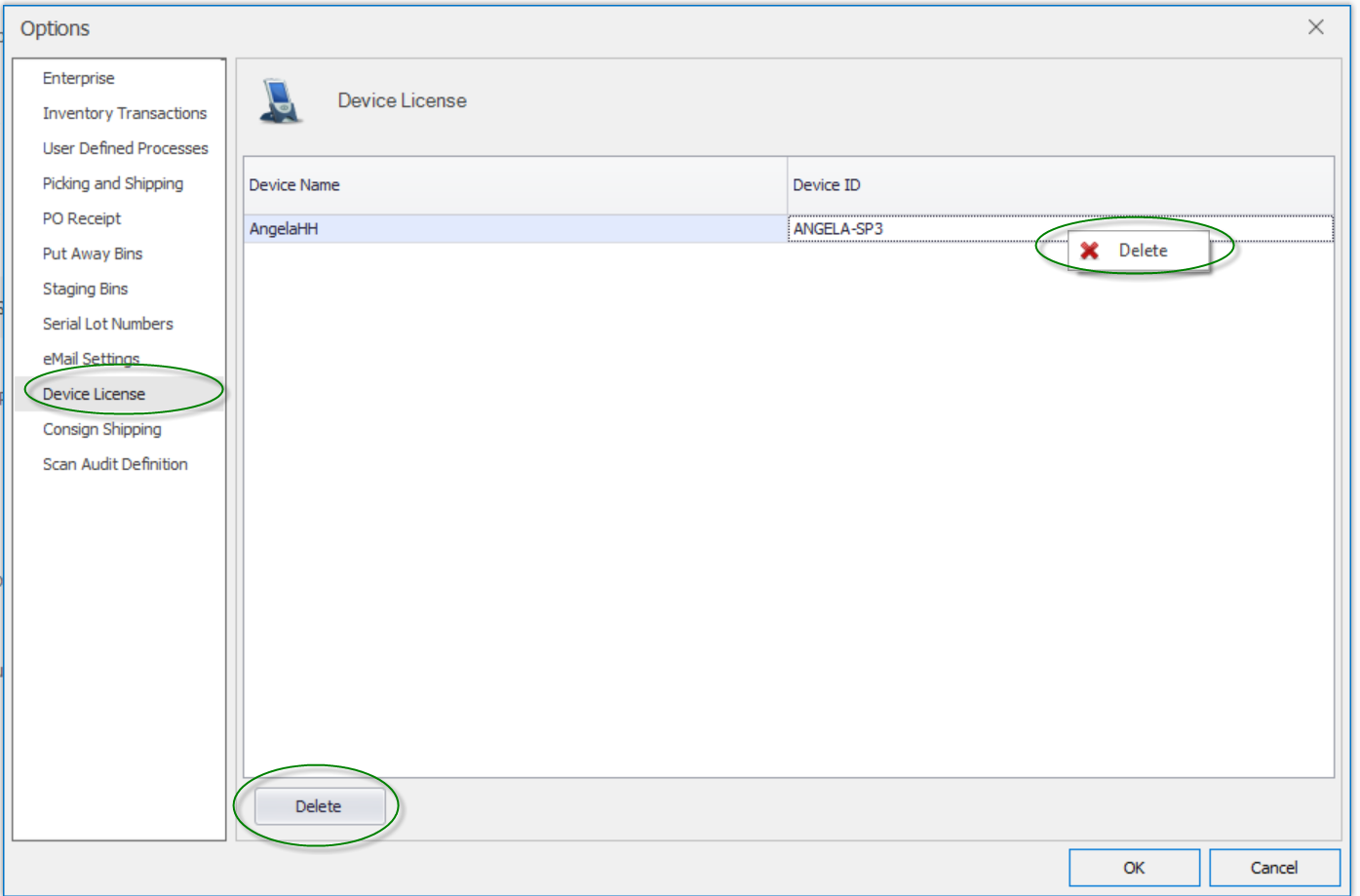

DEVICE LICENSE

When a handheld device is first set up it is assigned a device name. When the name is assigned the system also assigns a device ID. If for whatever reason a handheld device is replaced, then the device needs to be removed from the list of devices in the device license list to free up the license. Then when the new handheld device is assigned a device ID there is one extra license available.

To remove a device, highlight the device in the listing and click the "Delete" button, or right click on the device in the listing. Select "Remove" to remove the device. The space will now be free for adding a new device.

Figure 18: Removing Device License

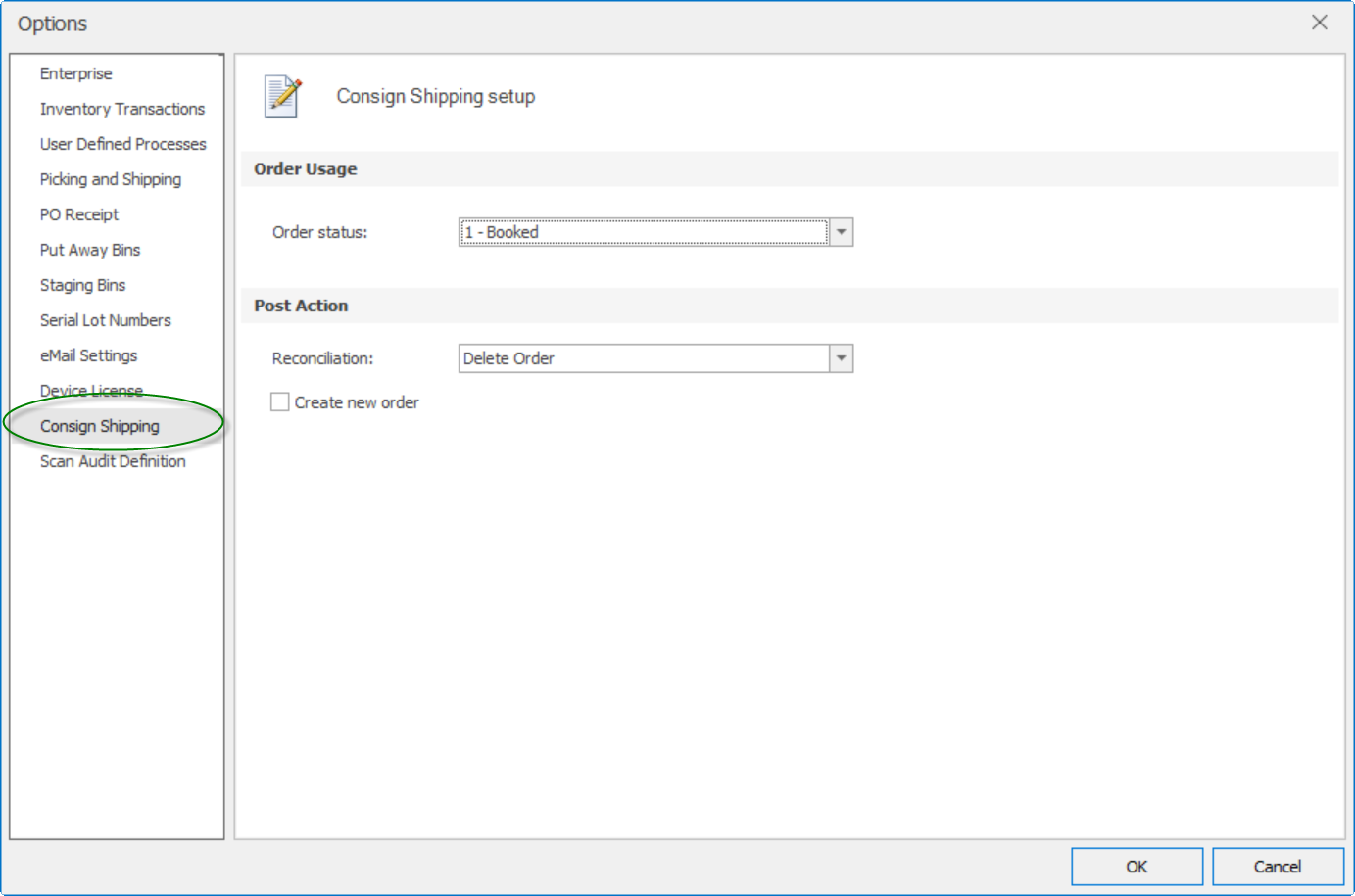

CONSIGN SHIPPING

Consign Shipping is a process by which one can ship consignment inventory to a customer location. Consignment inventory is inventory that physically resides at the customer location but the customer does not pay for until it has been sold to their customer. Therefore, the orders are shipped to another location but not billed and invoiced until the customer has reported back how many have been sold. At that time, a new order is entered into the system for the quantity sold so the material can be shipped from the consignment location, billed and invoiced.

Figure 19: Consign Shipping

Order Usage

Order Status: Select from 1-Booked, 4-Pick Ticket Printed, 6-Picking List Printed, 7- Confirmed Shipped or 8- Confirmed Billed

1-Booked: The consigned post grid will display all booked orders with a consignment alternate address populated for that customer.

4- Pick Ticket Printed: The consigned post grid will display only those orders for customers with a consignment alternate address defined in Agility Consign Post and for which pick tickets have been printed.

6-Picking List Printed: The consigned post grid will display only those orders for customers with a consignment alternate address defined in Agility Consign Post and for which a picking list has been printed.

7-Confirmed Ship: The consigned post grid will display only those orders for customers with a consignment alternate address defined in Agility Consign Post which have been confirm shipped. This is the most common configuration.

8-Confirmed Billed: The consigned post grid will display only those orders for which customers with a consignment alternate address defined in Agility Consign Post and which have been confirm billed.

Post Action

Reconciliation: Select from Delete Order or Cancel Order. The order will either be deleted or cancelled in Macola after the inventory has transferred to the consignment location.

Create New Order: Check this box to create a new order in the consignment location for the quantity transferred after the consigned post process is completed. This is not a common practice.

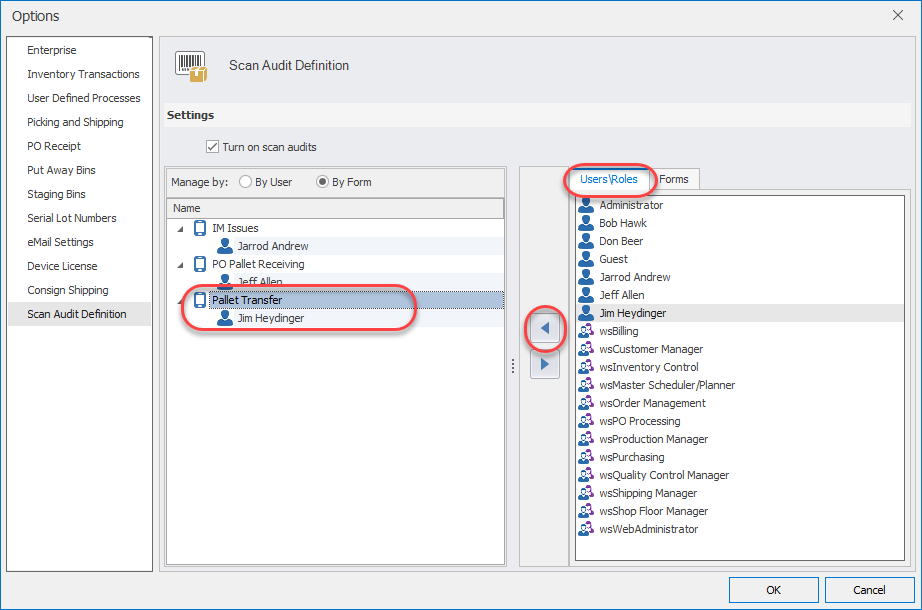

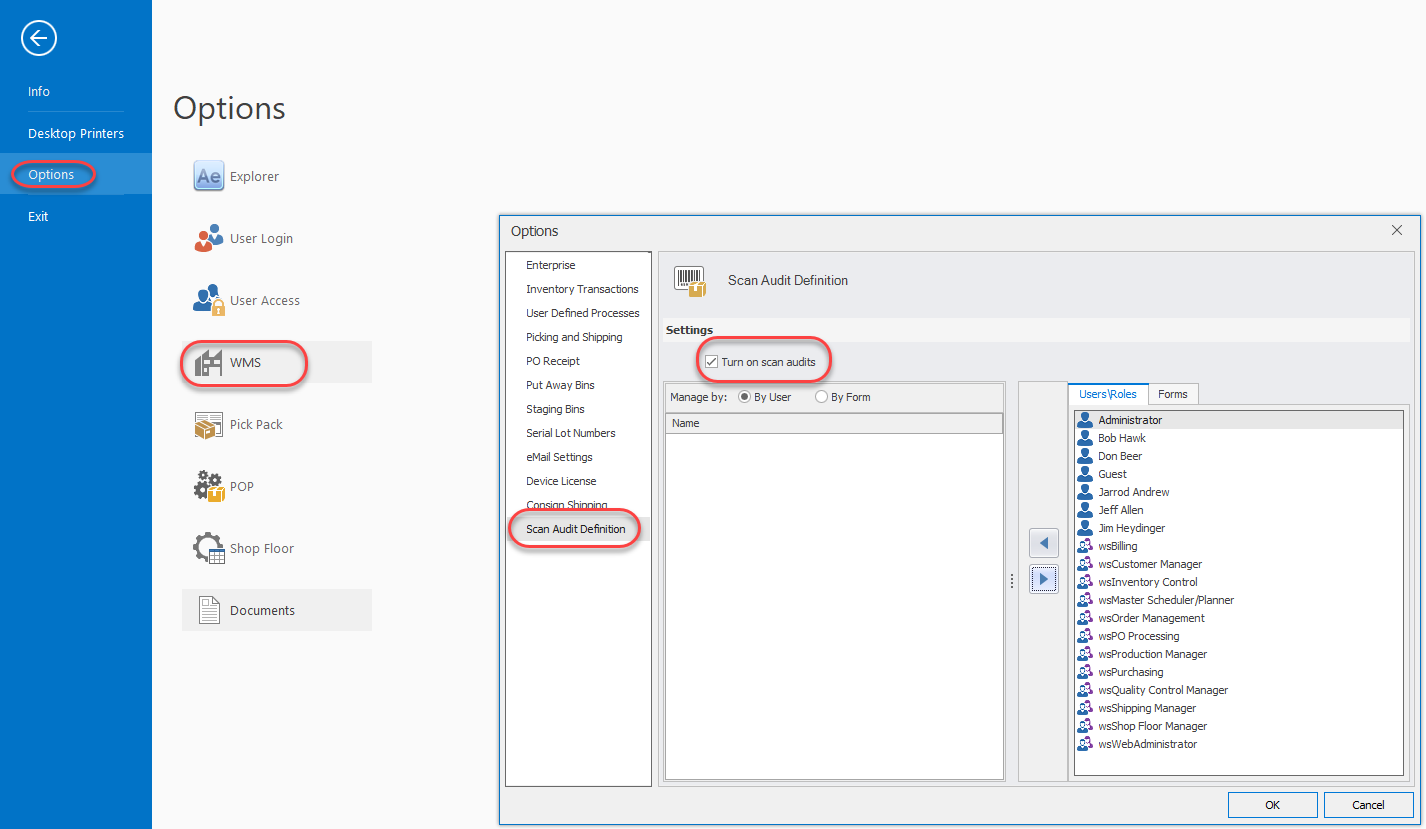

Scan Audit Definition

Figure 20: Scan Audit Definition

The scan audit trail can be set up by Forms and Users\Roles in the right-hand column. Click the box labeled Turn on scan audits. Next select the User\Roles or Forms from the column on the right. Double-click or use the arrow keys to move the selected entry to the left column. If you want to audit only a specific User or role that uses that form, double click to further define the audit. If an application form is added with no specific users, all users of that form will be tracked. If any users are added, only the added users will be tracked.

Managing By User will generate and audit record each time the specified users scan a barcode or press enter on the handheld. Additionally, specific forms can be added to the user to limit the audit results to the forms specified for the user.

Managing By Form will generate and audit record each time a user scans a barcode or presses enter on the form. Additionally, specific users can be added to the form to limit the audit results to the users specified for the form.

Figure 21 – Enabling Scan Audits

Open Agility – Options – WMS – Scan Audit Definition.

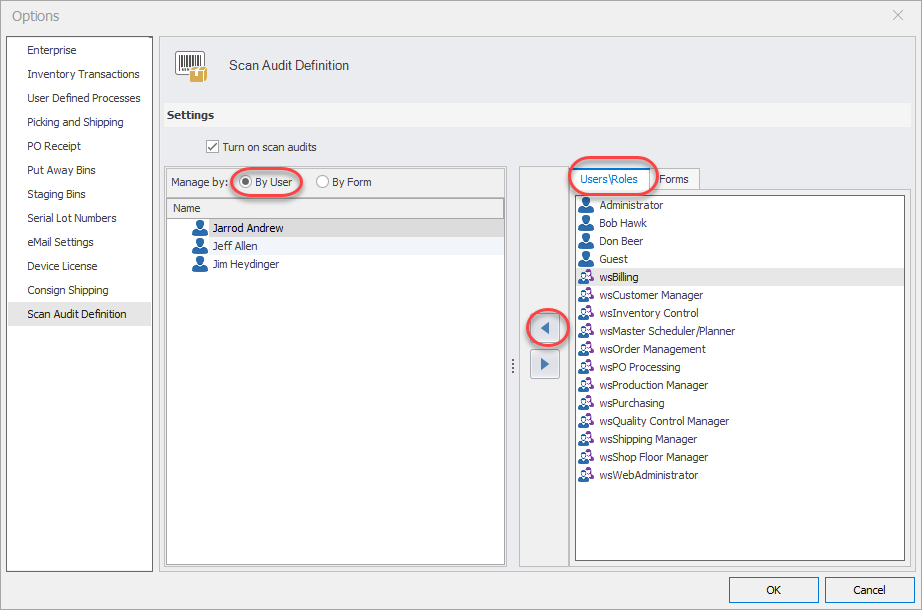

Figure 22 – Manage Audits By User

Select the Manage by User Radio Button. On the Users\Roles tab, highlight the users to be added and click the arrow to move the users.

This will generate audits for all forms used by the selected users.

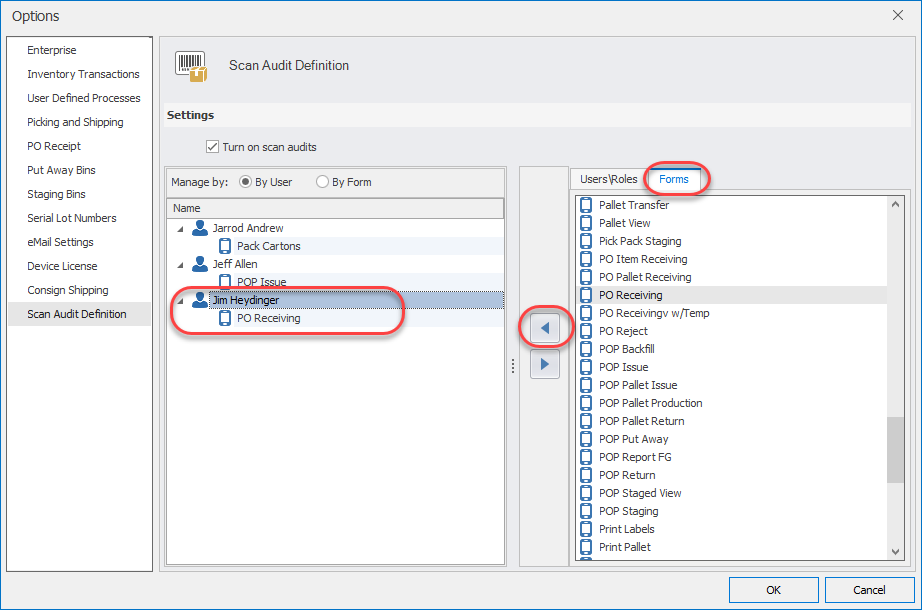

Figure 23 – Adding specific Forms to Users

Forms can be added to users to limit audit records to specific forms used by the individual users.

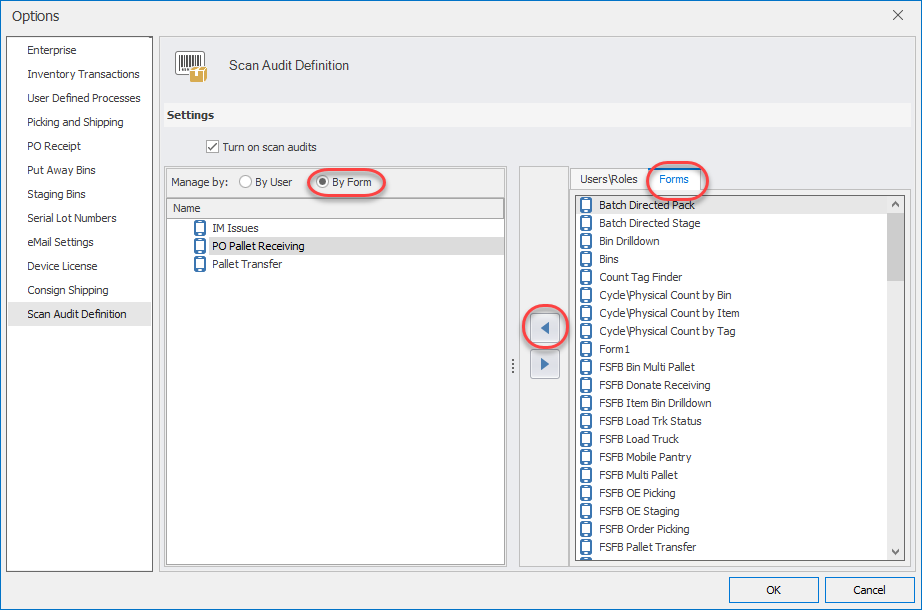

Figure 24 – Managing Audits By Form

Select the Manage by Form Radio Button. On the Users\Roles tab, highlight the forms to be added and click the arrow to move the forms.

This will generate audits for all users of the selected forms.

Figure 25 – Adding Specific Users to Forms

Users can be added to forms to limit audit records to specific users using the selected forms.